When we start talking about the circular economy, we quickly realize that Eco-design and Industrial and Territorial Ecology are crucial pillars of the approach. Why? Because Eco-design invites us to think about the product over its entire life cycle. That is to say to integrate from the design stage what will be, or not, its end of life. We talk about an approach going from the « cradle » to the « grave », or even from the « cradle » to the « cradle ». The production of anything induces a loss of materials. This is the original meaning of the word waste. It is what falls from the work of a matter. It is in particular what occurs when one cuts in plans of wood, metal, fabric… there are residues, what one does not keep. As for the industrial and territorial ecology, this one intervenes in a context where the interaction and the mutualization of the flows of materials, energies, waste management, for an economic, social and ecological optimization, becomes necessary.

Our conversation with Johanne, founder of Normcut in December 2022 in Berlin brings some thoughts on these topics. We let you discover this passionate entrepreneur.

How did you come to create Normcut ?

Originally I studied psychology but I always thought I would like to do something with my hands, like carpentry, so I always built things. When I was a kid, I was dealing in junk. I was 6 or 7 years old and people were too lazy to return their bottles, although for bottles you get up to 70c€ with the deposit. So with my friend, I used to ring the doorbell and say « Hey, do you want us to take your bottles back? ». I was making some pocket money.

I’ve always been interested in building things out of garbage, but also out of other things. I did my PhD in cognitive neuroscience on the neural mechanisms of decision making and belief, and I combined that with philosophy.

Meanwhile, one of my friends called me and said, « We are a group of friends who want to build a boat or a raft, do you want to join us because we know you can build things. »

I joined that group and said, « We should make it out of garbage. » They thought that was a good idea and they said to me, « If we’re making plans, shouldn’t we make them open source? » I said, « Yes, of course. » We built a 12-meter boat in open source up-cycling. To collect waste, I talked to garbage collectors in Berlin and after 50, 60 phone calls and hundreds of emails, a PR manager from the biggest German company called me and said, « Okay, I want to help you. » After that, all doors were open, I could go to any recycling center in Berlin and pick up material.

At that point, I was still doing my PhD, so I was still in that mindset about decision making, I was like, « OK, wait! There’s a lot of value here. What’s the big deal? Why is this here? Why is this garbage…? ». So I was thinking about it very « systematically » and applying principles of cognitive science or behavioral economics.

I don’t know if you know this study – Delay Discounting – where you ask a kid if they want 1 piece of candy now or 2 pieces of candy a little later. The kid almost always takes 1 now. Which is not rational because in terms of maximizing value you just have to wait a little bit to take two.

I think that’s one of the fundamental principles that is at the root of the waste problem. People produce, but they don’t think about the subsequent impact. This is a natural thing that you find in rats, monkeys, humans, fruit flies… Yet, in logic, to start doing something with waste, you have to start thinking about it before it is waste.

As a result, I realized that I wanted to do something with waste.

Normcut birth

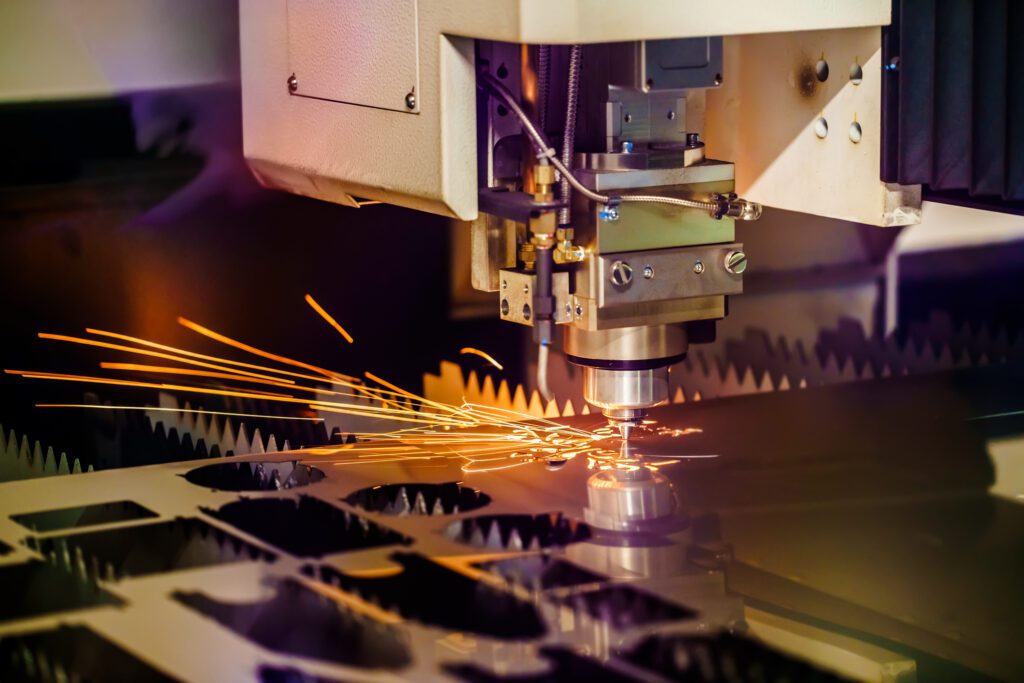

With my experience in building boats from waste, I started a small business. We started with rafts, then did interior decks, integrating team psychology into office design. That’s when I got into the production world with laser cutting machines. For this business, I was stocking everything and I noticed it was getting expensive to stock. And if you don’t have a perfect Information System, it’s more expensive to sort and make plans on what you have in stock, in different sizes than to just order online what you need. So I started thinking about ways to minimize that economic loss. Because you pay for the material up front, and at the end you pay to get rid of it. So you pay twice.

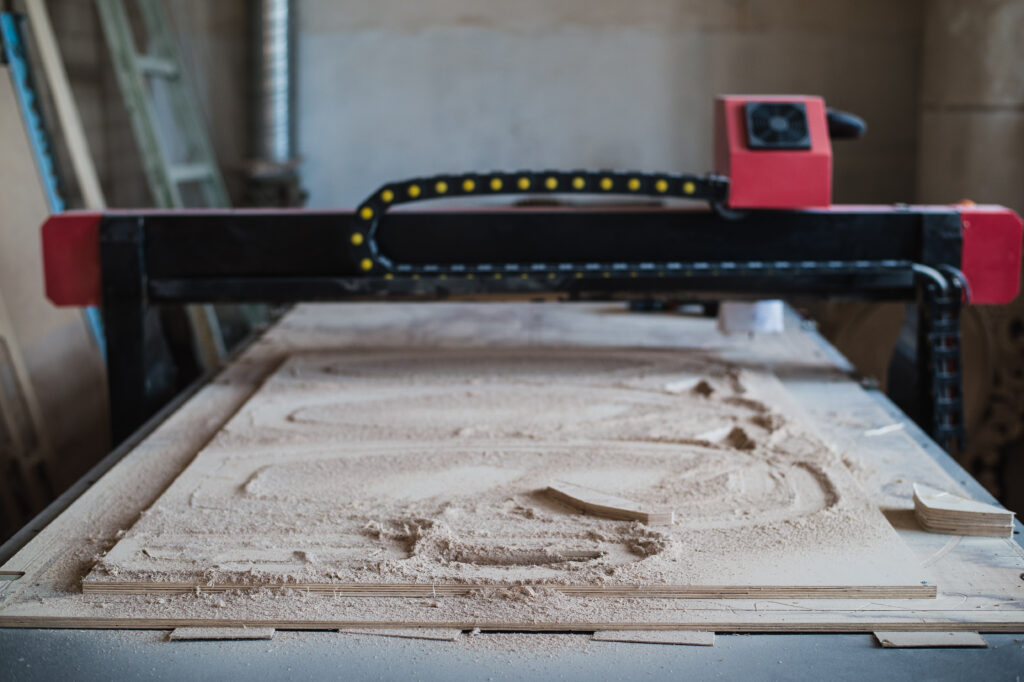

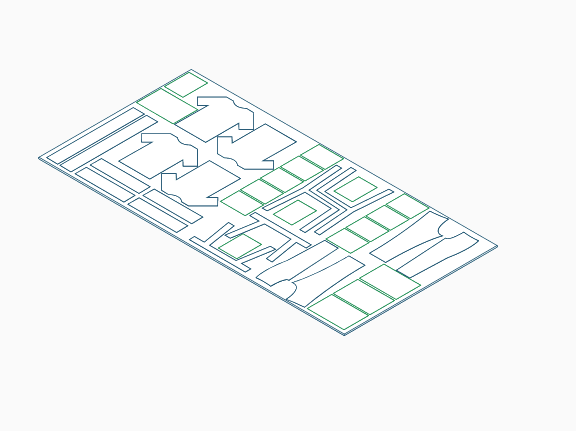

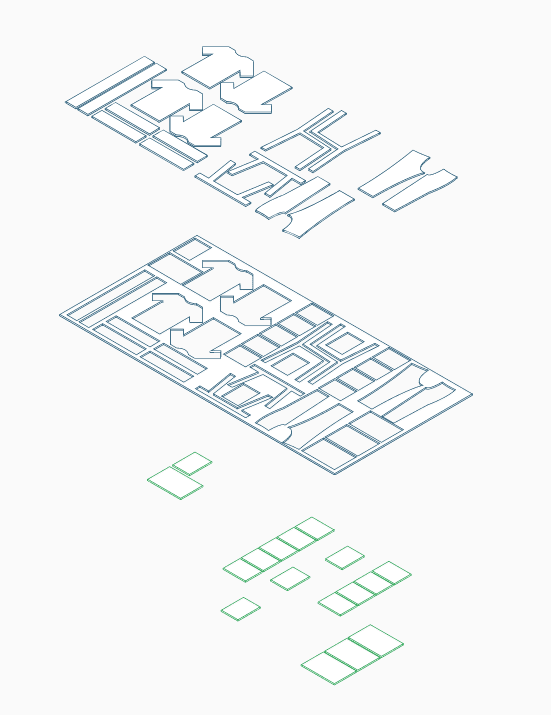

I tried different things and realized that you could optimize a lot of things, like optimization cuts on cutting planes. I thought, « OK, wait, this is a super general problem. »

The general problem is this: at Christmas, when you’re baking cookies, you try to arrange the cookie shapes as close as possible, to get the most cookies. Yet, no matter how well you do this, there is always waste to the left or right. You can’t avoid it, it’s a logical problem, and it turns out to be one of the trickiest optimization problems, and the algorithmic solutions are very expensive.

This is not just a problem for your cookies, it is a problem that probably any industry faces when cutting metal, wood or textiles.

Think about what is not cut, like 3D printing, for example, or molded items like plastic for example. There is no waste. But all the rest of the raw material that we use is cut or machined, in any country. But this is an abstract problem. We, as consumers, are not aware of it, it is not visible.

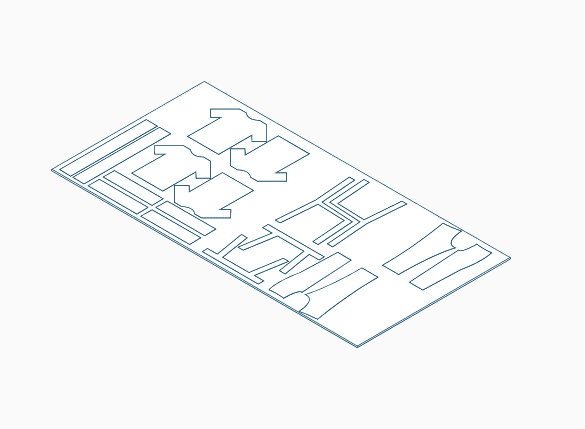

So I tried to approach the production planning sector, it’s the only place where they have information about the size and the off-cuts, and it’s a very important information for waste management, because before it’s waste you know what you’re going to lose on your cutting plan. So you can work on that to improve it.

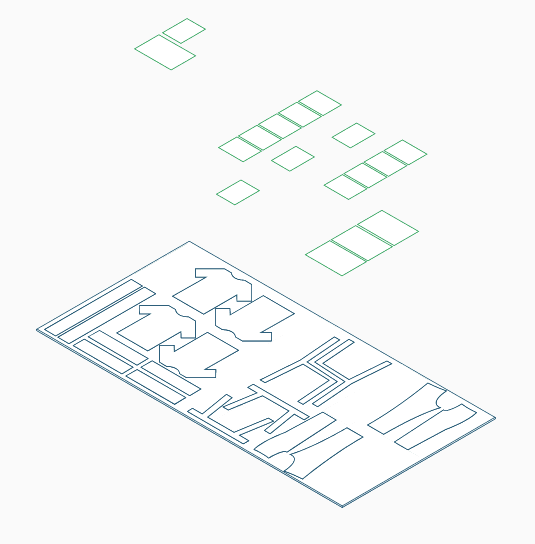

As a result, Normcut offer is an optimization software in the cloud connected by a replication system called slim plugins. People who do CNC cutting, they can use it locally, but the algorithm works in the cloud. The objective is to see the remaining spaces and to say, as the base of the industrial leftovers is on average 25%, we can insert smaller parts at the request of third parties to bring down this average of leftovers to 8%.

Involvement of manufacturers

If you want to do something about waste on a large scale, you have to get into production planning. Nobody does that today, they’re like, « Oh, there’s waste and we need to do something about it » or « We need to teach people to act more sustainably. » Of course, that’s important. But when you think about the economic system, and the industrial production system as it operates today, it’s obviously dysfunctional. So you have to look at the system as a whole, and see where you can make connections. For example, when I first started talking to companies, I talked to people who do optimization software and I said, « Hey guys, look, there’s a link to recycling. They said to go to the recycling department. Afterwards, I talked to the recycling people and told them that they could get data and optimize their processes. But they said they only deal with recycling. Then I talked to the production people. Let’s say, I have 80 users, 20 of them cut the same material as you, give me an order and I can distribute it to the remaining spaces of 20 aggregated companies and deliver it. They were interested in that, but they told me to take it up with the logistics people, to whom I said, « I have 20 places that cut your production, I’ll tell you when you can pick it up and take it somewhere. » They seemed overwhelmed by the task and decreed that it was complicated…

As a result, if you want to think about recycling at the production level, you first have to get the teams talking to each other. And if you also have to wait for the logistics to be what they should be; there is still time to wait.

However, if we want the circular economy to be economically viable and these issues to be addressed, there are two solutions: either governments stop « saving » companies as they do now with energy, raw materials …etc and tell them to realize that they have something to change. Or, new companies enter the market and disrupt the old ones or kill them, as it happened in advertising with Google and Facebook that killed some advertising companies. So there are two options, either they talk to each other (internally) or they die.

So for now, we’ve been focusing on optimizing the cutting plans of the organizations that work with us, I think when the logistic systems have developed more (a lot of start-ups are developing), the initial concept will work better.

To go further : Systemic thinking by Arthur Keller

How do these companies become Normcut clients ?

People use or are interested in our solution when there is a big difference between the price of the material and the cost of disposal. For example, metalworkers are not super interested because they always get a good price for scrap. So this price ratio upstream and downstream of production is interesting for them. But in textiles for example, they pay to get rid of their scrap. So the difference between the price they paid and what they will have to pay in the end is a driving force to use our services. With this solution, people can save material and improve their carbon footprint.

Price of raw material

Cost of elimination

The problem is that what matters to manufacturers is the price. For example, I talked to sustainable brands that say they produce sustainable packaging or good materials, I contacted them and told them that they probably have 25% of production waste, I offered them my solution, but after talking about things, in the end, it’s the price that counts, even for some so-called sustainable brands.

I’m sure there is a lot of expectation, especially in companies. It’s not the CEOs or the owners, with a few exceptions, like Patagonia, who are trying to move the needle, but it’s mostly the employees who are saying, « We need to become more sustainable or I’m leaving this company. » Management decides they need to do something about sustainability, but usually what management is interested in is a good brand image, if you can tell a good sustainability story, it’s an easier sell.

What reflexion about Normcut business model?

Concerning our business model, it is multiple but in the long term we would like to have an approach a bit like Google. That is to say, to have a monopoly of information on production waste. Our goal is to optimize as much as possible, to have as much data as possible.

One of the big problems of recycling is that the materials must be homogeneous and not mixed because the more they are mixed, the worse the quality is. So it’s pretty tricky to get homogeneous materials from post-consumer waste or to make a table like that, there’s no way that post-consumer waste is cleaner than post-industrial waste. And remember, it’s 25%. But it’s an economic approach to the data, so it’s a risky bet.

The way it works depends on the companies as in any digital economy approach, either you pay for access to the service or you contribute with data.

What are your challenges in scaling up Normcut ?

The biggest problem in scaling a project like this is finding investors, people who will believe in your project and potentially support you in creating the business, putting you in touch with the right people. But it’s really about the return, it’s like people are putting their money in there to make more money. If you hear about impact investing, these venture capital funds that say they only invest in things that have a positive impact. That doesn’t mean they don’t want to have a return on investment, they’re just asking for something different: they don’t just want you to make money, they want you to have an impact.

I think maybe we need more crises, more supply chain issues, because there is a problem for industrial production. If energy gets more expensive, if it really gets more expensive, your supply chain is interrupted. And then obviously people will start thinking about the circular economy. Under pressure, when they could have anticipated it…

But in the end, it’s the best thing that can happen. Crises make things change. In Latin, crisis means « change ».

This meeting with Johanne opens the way to different subjects that deserve to be discussed:

- Psychological processes are at the origin of our decision making

- Eco-design and reflection upstream of the production of a product are essential to drastically reduce our waste production

- Communication and interconnection within and between companies to sustainably impact our waste production is essential

- Companies as well as investors still operate exclusively on the basis of economic rationality, far from the primacy of any environmental reflection

We hope you enjoyed this ARTICLE about our meeting with Johanne Heereman. Feel free to discuss it with us in the comments or on our social networks.

Find all our articles HERE !